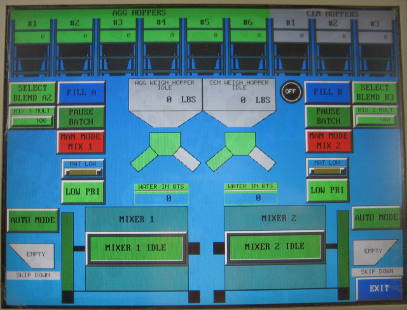

Batch Control Management

Our control systems for block and concrete product applications offer you a performance edge by combining speed, accuracy, flexibility and connectivity all-in-one system. Stand out against your competition by utilizing our batch control system that provides the following very unique competitive advantages:

Easy to Use

Our batch control systems are extremely easy to learn and operate. With simple, single key-press operation, on screen at touch troubleshooting and color coded status displays, anyone can learn to use the system in just minutes.

Color System Integration

Color System Integration

Our systems are made to work with your color systems ensuring you get the right amount of color every time, without having to invest in different equipment and color.

Custom Design

All our batching controls are designed specifically for your operation and can be easily configured to support multiple plants, mixers and machines. The material transfer timing and control logic is easily customized to maximize your operation’s throughput and efficiency.

Integrated PLC

Every batch control system includes an integrated Programmable Logic Controller (PLC) that allows every operation in your plant to be controlled, without adding costly relays and custom wiring.

Settable Timing

Our batch control provides flexible control of the introduction and timing of materials in the mixer. An on-screen display allows you to see at a glance what your mixer is doing at all times.

Speed and Accuracy

The unique, “auto inflight” system keeps track of each material fill and automatically adjusts for cut-off variations.

Aggregate Moisture Control

Using our moisture control system, you can keep track of the moisture in the aggregate and automatically make adjustments to keep your aggregate to cement ratio consistent from batch to batch.